Product Description

MICA - the mineral that glitters with a glimmer of hope responsible for shine of every women's face and brilliant metallic colors in cars & automobiles and the wonder insulation material.

The name "MICA" is derived from latin word MICARE which means ' to shine or glitter '. Mica is a generic term applied to a group of a complex aluminosilicate minerals having a sheet or plate like structure with different chemcial compositions and physical properties. All micas from from flat six-sided monoclinical crystals with a remarkable cleavage in the direction of the large surfaces,which permits them to split easily into optically flat films, as thin as one micron in thickness. When split into thin films, they remain tough and elastic even at high temperature.

What makes micas so important to command such a unique position ? Because it had been gifted with exceptional values. It possesses some of the most outstanding combination of chemcial, physical, electrical, thermal and mechanical properties which are not found in any other product.

Physical: Mica is transparent, optically flat, easily splittable into thin films along its cleavage, colourless in thin sheets, resilient and incompressible.

Chemical: Mica is a complex hydrous silicate of aluminium, containing potassium, magnesium, iron, sodium fluorine and/or lithium and also traces of several other elements. It is stable and completely inert to the action of water, acids (except hydro-fluoric and concentrated sulphuric) alkalies, conventional solvents, oils and is virtually unaffected by atmospheric action.

Electrical: Mica has the unique combination of great dielectric strength, uniform dielectric constant and capacitance stability, low power loss (high Q factor), high electrical resistivity and low temperature coefficient and capacitance. It is noted for its resistances to arc and corona discharge with no permanent injury, and has little or no effect when exposed to electronic radiation dosages up to 1018 nvt. Thus maintaining its a-c dielectric material when exposed to the oxidising action of electrical discharges either on the surface or within internal gas spaces in built-up mica insulation.

Thermal: Mica is fire proof, infusable, incombustible and non-flammable and can resist temperatures of 600oC to 900oC (1112oF to 1652oF) depending on the type of mica. It has low heat conductivity, excellent thermal stability and may be exposed to high temperatures without noticeable effect.

Mechanical: Mica is relatively soft and can be hand cut, machined or die-punched. It is flexible, elastic and tough, having high tensile strength. It can withstand great mechanical pressure perpendicular to plane but the lamination have cleavage and can be easily split into very thin leaves.

Some of the Mica Products are:

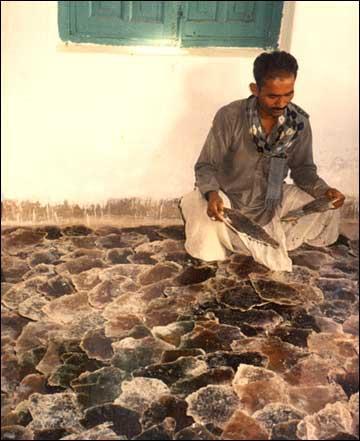

PROCESSED MICA: Natural Mica in sheets in irregular sizes and shapes, flat and nearly free from defects having minimum 4.8 sg. cm usable area suitable for punching, splitiing, cutting into specific shape. Products include Mica Blocks, Films, Thins and Splittings.

FABRICATED MICA: Natural mica cut, stamped or punched into specific sizes, shapes for industrial application. Products include washers, discs, cut films, spacers, bridges, boiler gauge etc for toasters, capacitors, appliances, transistor mica, strainer cores, backing, corrugated mica, mica discs, window mica plates etc.

MICANITE OR BUILT UP MICA: This is made from Mica Splittings or Mica Flakes by arranging them into a composite sheet with help of binders like epoxy, shellac or silicon for use in electrical insulation in motors, turbines etc. Products include Micanite sheets, Mica Folim, V rings, Commutator segments, Tapes etc.

MICA PAPER OR RECONSTITUTED MICA: This is made from Mica Scrap and waste in similar process as used in making ordinary paper. The Scrap is converted into pulp and then making it into Mica paper using different binders. They can be added together to make boards etc for insulation.

GROUND MICA OR MICA FLAKES & POWDERS: The samller sized mica which is smaller than Mica Scrap are processed to convert them into Mica Flakes with size of 2-10 emsh or Mica Powders from 10 mesh onwards upto 325 Mesh depending on buyers requirement for use in wet grinding, pearl pigments, rubber and plastics, sound acoustics, electrodes, joint compounds, tar felts, etc.

SPECIFICATIONS

Chemical:

Silica--- 44 - 47%

Alumina--- 30 - 38%

Iron Oxides--- 0.2 - 5%

Potassium Oxide--- 8.5 - 12%

Sodium Oxide--- 0.1 - 0.8%

Titanium Oxide--- 0 - 0.9%

Magnesium Oxide--- 0.3 - 1.5%

Calcium Oxide--- 0.1 - 0.5%

Lithium Oxide--- Trace

Phosphorus--- Trace

Sulphur--- Trace

Loss on Ignition--- 4 - 5%

Physical:

Formula--- KAl2(Si3Al)O10(OH)2

Color--- Colorless to light green / ruby

Density--- 2.6~3.2 x 1000 kg/m3

Hardness--- 2.0~3.2 Mohs

Specific Heat--- 860~870 J/kgK at 25oC

Decomposition--- 600~800 C

Wt. loss at 900C--- 4~5 after 3 hours

Dielectric Strength--- 18~25 kV/0.1mm

Dielectric constant--- 6.5~9 at 50 Hz

Tensile Strength--- 1750 kgf/cm2

Other Products in 'Mica' category

GST : 19ADDPA3542P1ZF

|

|

|

|

|

HI RISE EXPORTS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |